A Practical Approach to Bring Improvement Projects to Life With PuMP

by Stacey Barr |Performance improvement momentum can be hard to maintain. PuMP Contractor, Ayça Tümer Arıkan, shares a practical approach that blends PuMP with improvement cycles.

I have been facilitating PuMP projects for a while now, and I have observed two issues with my clients that can prevent the benefits of the measurement process to be realized as intended.

Two reasons performance improvement doesn’t get implemented.

One issue is not being able to bring the improvement projects into life as planned. This happens when daily work and “urgent” things come into the way! As time passes, and the improvement projects are delayed, achieving the intended results are also delayed and the motivation for using measures to improve performance which was previously in place can be lost.

Improvement projects shall be planned and managed like formally approved projects for sure, with an assigned Project Manager, a team, and a schedule and budget – improvement projects or initiatives are where the budget for improvement is used, remember. But sometimes, even if it is the case, daily work and urgent things can still come into the way.

The second issue I observed is the challenge to make improvement effort a continuous part of the routine work within an organization. Most of the time this happens especially when using measures to improve process performance is new to an organization.

I was searching for solutions for resolving these issues and recently, I came across a practical approach for selecting and managing improvement projects in a webinar I attended. The webinar was called “Six Weeks to Success: How to double your output and half your stress by using 6-week improvement cycles”, which was organized by Kai Nexus. The presenter was Simon Murray, who is the founder of Your Maintenance Coach and has more than 20 years of experience in leading and coaching high performance manufacturing teams and is specialized in continuous process improvement.

The method presented was inspired from a book called “Shape Up: Stop Running in Circles and Ship Work That Matters” by Ryan Singer, and was being used by Simon Murray as a method to speed up and keep improvement effort sustainable for his clients.

Use two weeks to select the improvement and six weeks to implement.

The method suggests a cool down and improvement project selection period of two weeks followed by 6 weeks of project implementation, a total of 8 weeks of improvement iterations which are kept running continuously.

The ideas or suggestions are collected in a “pitch” where they are filtered and aligned to business goals, then selected ones are transferred into a project list. Then with a “betting table” step, what to work on is prioritized and selected according to how easy to implement versus the degree of impact. Then a project plan is prepared for the selected project – a visual plan where only the outcomes are listed.

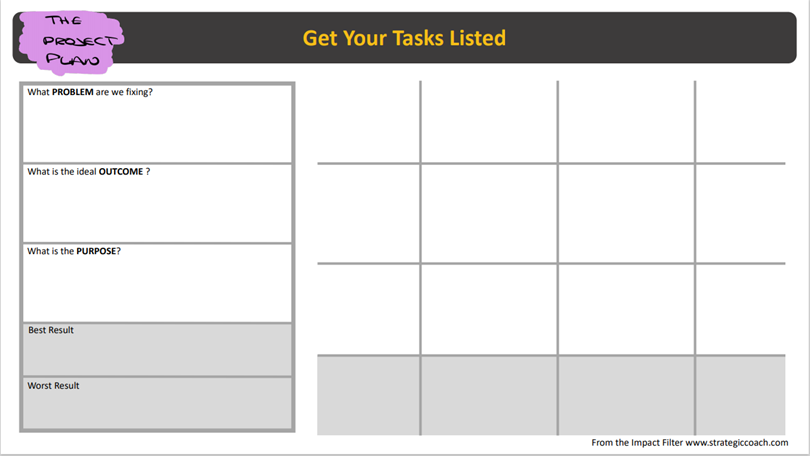

A template like the one below is used to document the plan:

Make performance improvement project progress visible.

And finally, the implementation is tracked with a visual project tracking template, which is kept on a wall. The planned outputs are written on post-its and moved towards the “done” area of the tracking template as the project progresses and finally completes.

The Project Tracking template looks like this:

PuMP has a role in performance improvement.

This method seemed very practical and meaningful, however I think PuMP provides a better approach to selecting an improvement project:

- PuMP suggests that you should clarify your goal first then meaningfully measure it

- Then you should identify the causes of the gap between as-is and to-be performances

- Then you should select the highest ROI solution to close the gap – which then becomes an improvement project

The method presented by Simon Murray on the other hand, suggests that improvement projects should be continuously selected and implemented from a project list as described above. Even though it is good to be

continuously working on improvement projects and making it a part of the routine work and culture, the link to strategy can be weak and there is no guarantee that the best projects are chosen.

After giving it some thought, it seemed meaningful to integrate some of the beneficial steps of the suggested method with PuMP, which could be a practical solution to both of the issues that I mentioned in the beginning.

Blending PuMP with improvement iterations…

Here is what it could look like:

| 1. | Plan 14-week PuMP iterations plus project implementation as follows: |

| Week 1: Select a process or process activity result to work on from the Results Map (assuming you already have a map). Clarify the process activity level goal that is directly linked to a process level result in the Results Map.

Week 2: Perform Measurability Tests to the process activity level goal (PuMP Step 2). Week 3: Design a measure for the performance result (PuMP Step 3). Week 4: Organize a mini Measure Gallery for the one result and one measure with the related stakeholders and get their feedback. Week 5: Define the measure. Week 6: Collect data and review the as-is performance. Give a target. (Add the measure to an already existing report.) Week 7-8: Perform root cause analysis and select a solution. Plan the improvement project (as Simon Murray suggests with a similar template). Weeks 9-14: Implement the project and track its progress with the Project Tracker template as Simon Murray suggests. Note, however, that the 14-week schedule may not be appropriate for each PuMP iteration plus project implementation, but it can be used as a starting point. With more experience, the time spent for the PuMP steps is expected to decrease. For example, it would be possible to run Steps 2 and 3 in one session. The duration of the improvement project though, can vary depending on the scope of the project. |

|

| 2. | For projects that can be completed in more than 6 weeks, ensure that an output is completed and an outcome is achieved at the end of each 6-week iteration (which was suggested by Simon Murray, and I completely agree). |

| 3. | When the improvement project is completed, wait to observe the result. |

| 4. | If a performance improvement signal is observed as expected, celebrate and select/identify the next performance result to work on. This would mean identifying a new orange layer result (process activity or team level) that would improve a blue layer result (process or department), or identify a blue layer result to work on that would improve a strategic level result. |

| 5. | If a performance improvement signal is not observed, go back in the process and repeat the iteration for the same result until an improvement signal is observed. |

After starting to implement this approach with a client as a pilot, here are the benefits that we could quickly observe:

- Keeping the improvement projects visible all the time makes it hard to forget and let “urgent” and daily work get into the way.

- There is increased motivation within the implementer teams since the method is a fun way of tracking a project.

- It attracts the interest of other teams by creating curiosity and motivation to be included in the process.

The following is another benefit that I believe will be observed in time:

- Teams learn and improve their own processes as part of their routine work, by identifying new orange level results to achieve and improving their performance on a continuous basis.

This method definitely supports one of PuMP’s messages that I love: “Success loves speed!” Keeping and tracking the improvement projects on the wall surely supports to keep the pace, since well, you know what you keep in sight, would not be out of mind!

Performance improvement will only be successful when it’s made to be part of routine work, not extra to it.

[tweet this]

Connect with Stacey

Haven’t found what you’re looking for? Want more information? Fill out the form below and I’ll get in touch with you as soon as possible.

167 Eagle Street,

Brisbane Qld 4000,

Australia

ACN: 129953635

Director: Stacey Barr